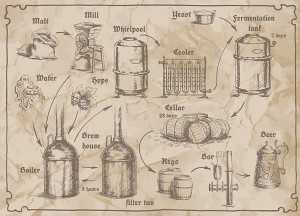

The Brewing Process

The delicate combination of just four ingredients results in that delicious beer we serve.

Water. Barley. Hops. Yeast.

Water makes up the largest percentage of beer. Our water travels a very short distance – from the snowpack at the top of Buff Pass about 13 miles away to the brewery. Quality water is essential to getting the most out of the other three ingredients that comprise beer. Check. We’ve got that one handled.

Barley is steeped in water until it germinates then is slowly dried and roasted to specifications. Adding different roasts of malted barley in different quantities creates a diverse array of styles. It is primarily responsible for the color and body of the finished beer and provides a source of fermentable sugar for the yeast.

Hops are soft pinecone-like flowers that grow on tall vines. Usually they are added to the wort during the boil and are responsible for the bitterness and aroma characteristics of the finished beer. Dry-hopping is the process of adding whole dry hops to the beer after fermentation, while it is aging, to give additional aroma.

Yeast makes the party happen! Yeast is a living organism that converts the fermentable sugars from the wort into alcohol and CO2, making beer. Different types of yeast make different types of beer.

During the brewing process, malted barley is gently cracked to expose the starch inside. This cracked malt is then mixed with hot water to form a mash during which the starch is converted to fermentable sugar. The starch dissolves and the resulting liquid is separated from the spent grain. This liquid sweet water called “wort” is then boiled, hops are added to season the brew and balance the sweetness of the malt. The boiled wort is then cooled, yeast is added (“pitched”) and fermentation takes place for one to two weeks. After fermentation the beer is chilled and cold-conditioned for one to four weeks depending on beer style. After this point the beer is ready to be served and enjoyed!